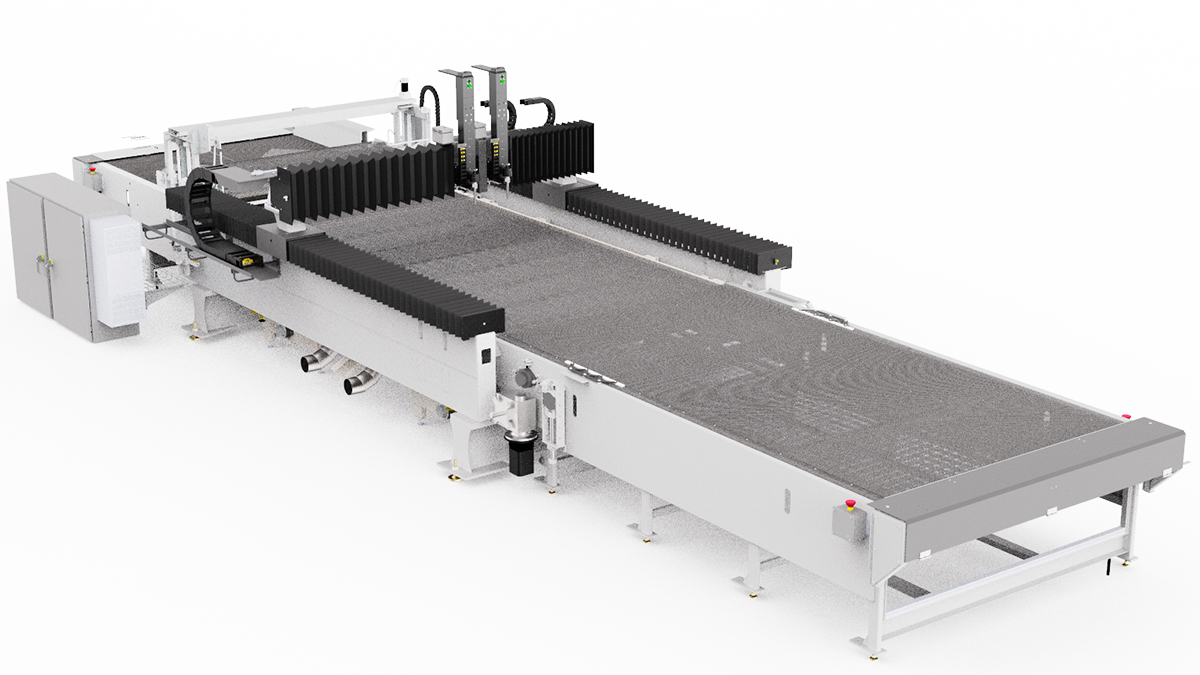

Many of today’s waterjet cutting systems are capable of raising and lowering the height of the water in the tank. Depending on material thickness, water level control allows the operator to completely submerge a workpiece underwater. Cutting underwater has many benefits including noise reduction and a cleaner work environment.

Noise Reduction

A waterjet that is cutting above water can generate a significant amount of noise. Waterjets propel a mixture of water and abrasive out of the cutting head at nearly three times the speed of sound, the force of which almost instantaneously erodes whatever it comes into contact with. It is not surprising then that these machines produce a sound loud enough to warrant ear protection. By cutting underwater, however, the level of operational noise is massively reduced. The water between the cutting nozzle and workpiece muffles the sound, eliminating the need for hearing protection and allowing for conversation at a normal volume.

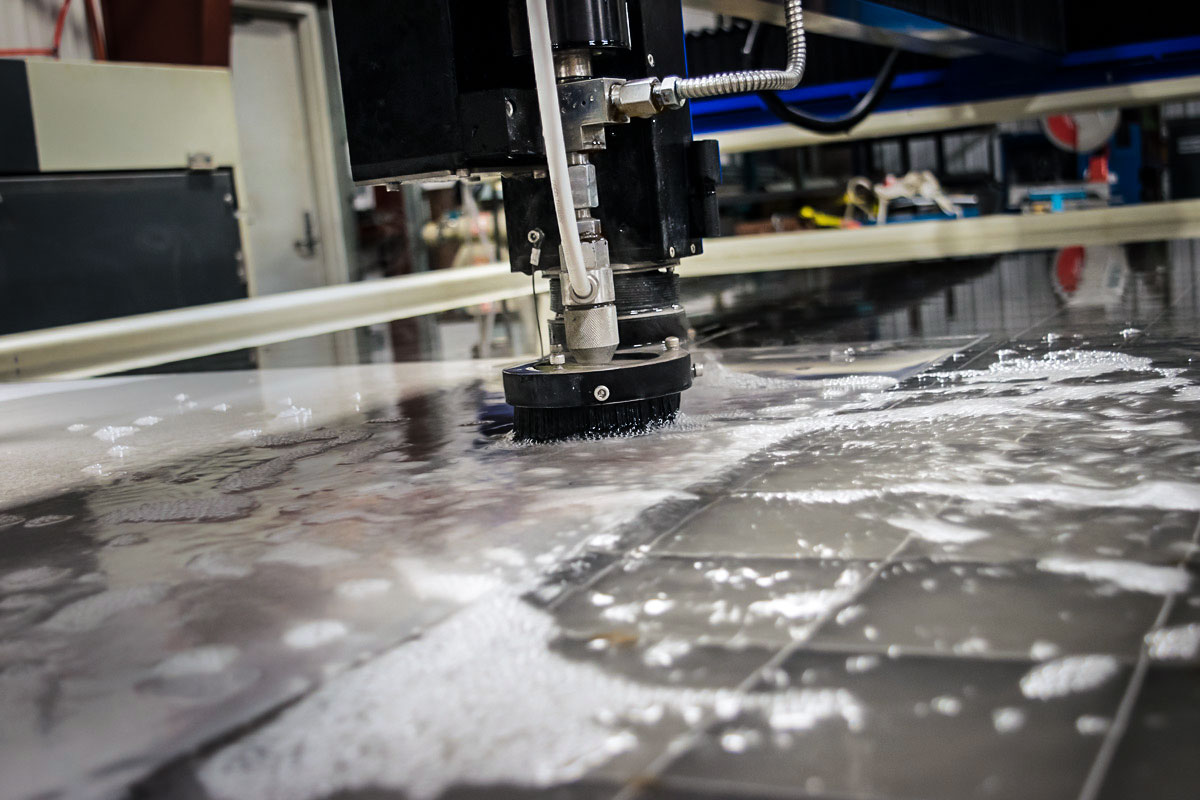

Cleaner Work Environment

As the waterjet stream pierces a workpiece, a combination of water and abrasive bounces off of the surface, producing splash back. The amount of splash back created while cutting can be reduced by cutting underwater. This reduction can be amplified through the use of splash guards both around the cutting nozzle and the perimeter of the tank. Reducing splash back results in less abrasive dust in the air, less water around the machine, and a cleaner overall work environment.

Reduce Frosting

In the waterjet industry, frosting is a cloudy or rough appearance on the surface of a workpiece. Frosting is caused by stray abrasive particles leaving the cutting head and striking the surface of the material. Cutting underwater can help to reduce the amount of stray abrasive particles, and in turn the amount of frosting that appears on a workpiece.

Reduce Onset of Rust

The abrasive waterjet process causes splashing in the tank water that can soak the workpiece when cutting. This constant exposure to both air and water can accelerate the development of rust on certain metal materials. When cutting underwater, however, the workpiece’s exposure to air is reduced which can help to prevent the quick onset of rust.

Water level control is a feature that brings about many benefits. For more information about water level control or WARDJet products and applications, fill out our contact form.