Industries We Serve

We've built and installed thousands of waterjet machines across a diverse industry portfolio to suit specific manufacturing and material cutting needs.

30+

Years OF WATERJET EXPERIENCE

40+

waterjet accessories

100+

million waterjet combinations

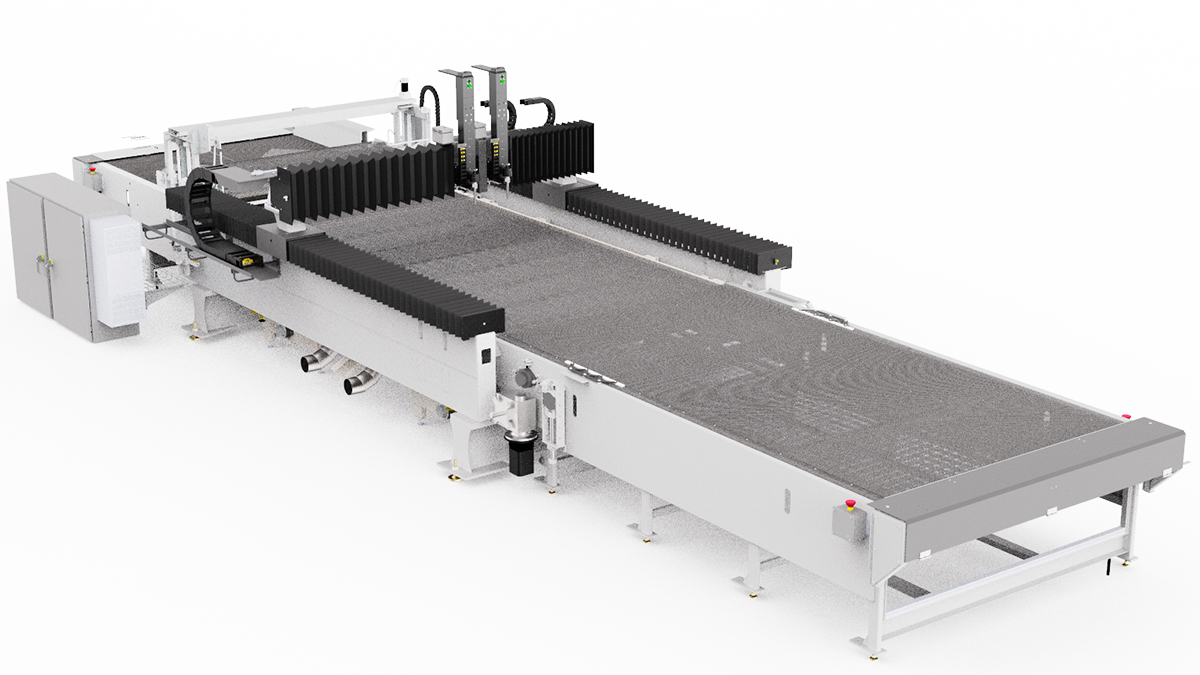

Products We Sell

Our modular products can be tailored to fit your needs and provide a perfect solution to your challenges.

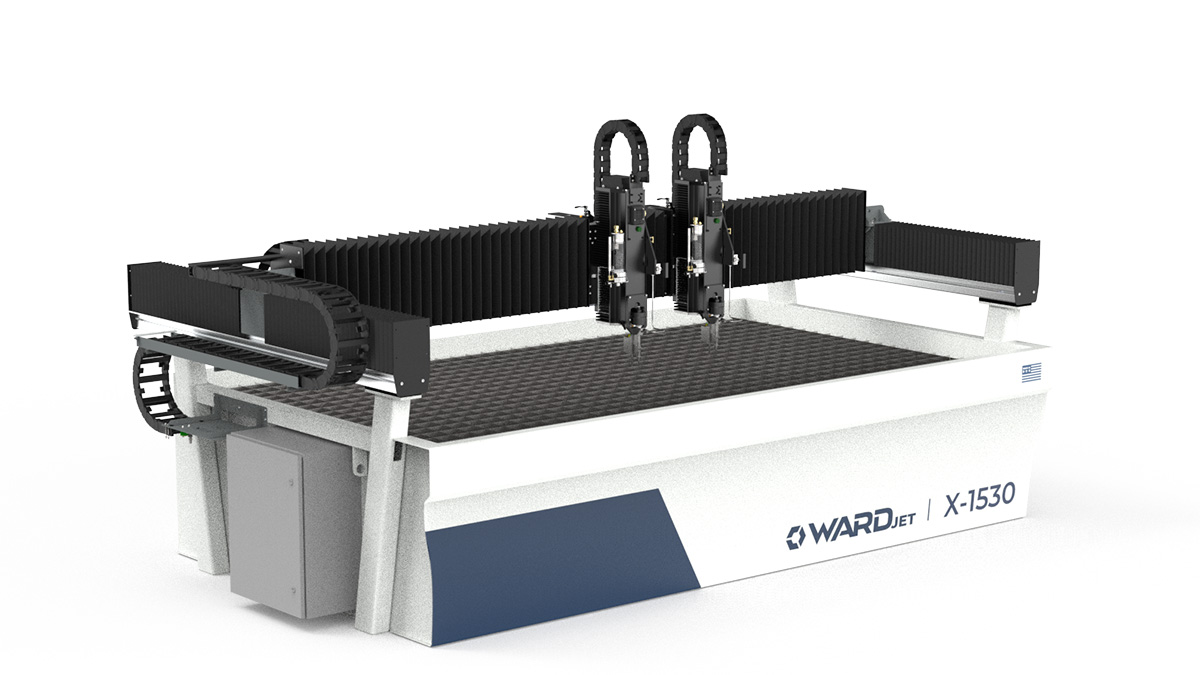

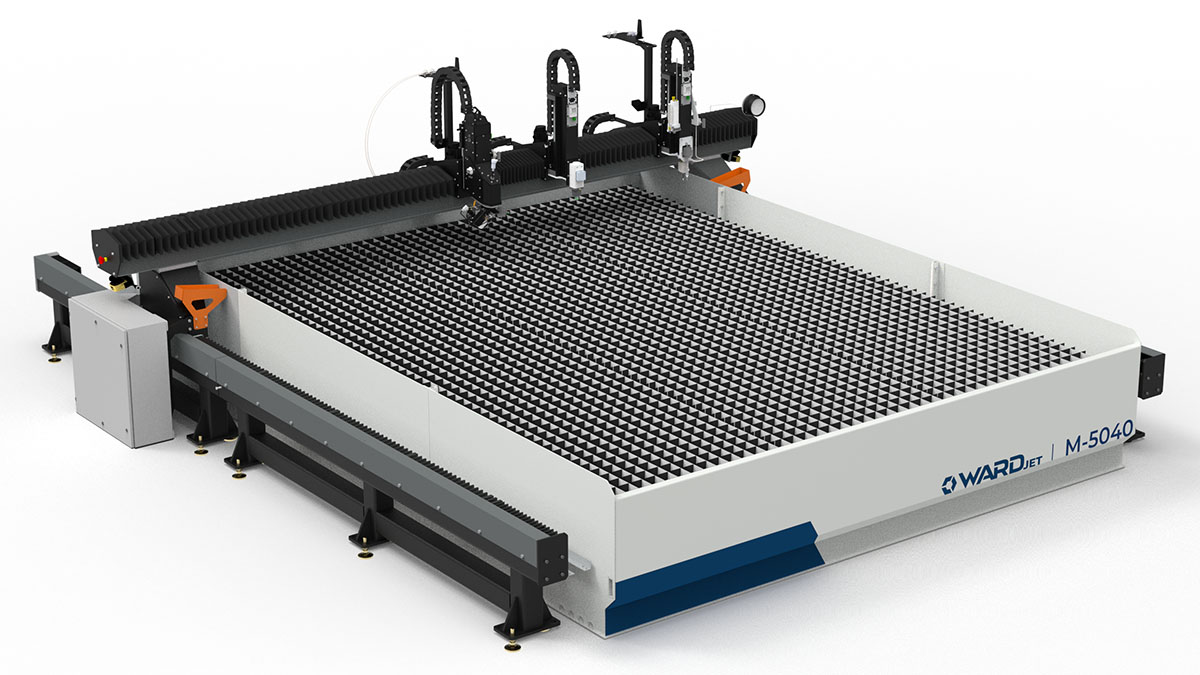

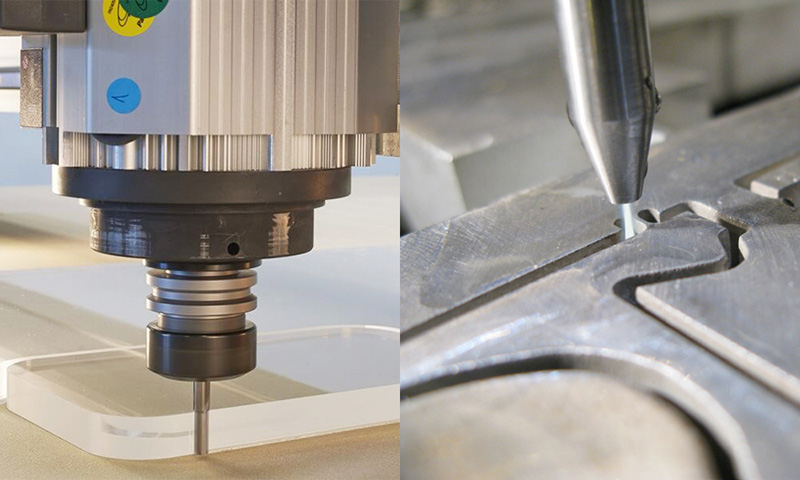

Abrasive Systems

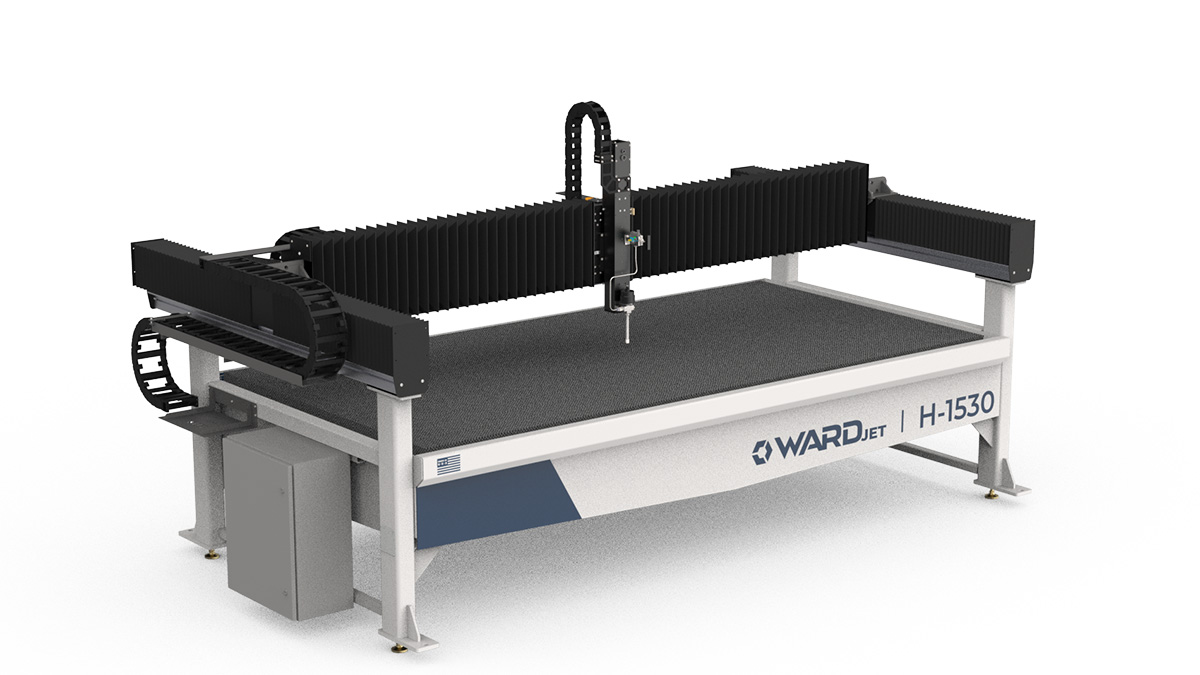

Water Only Systems

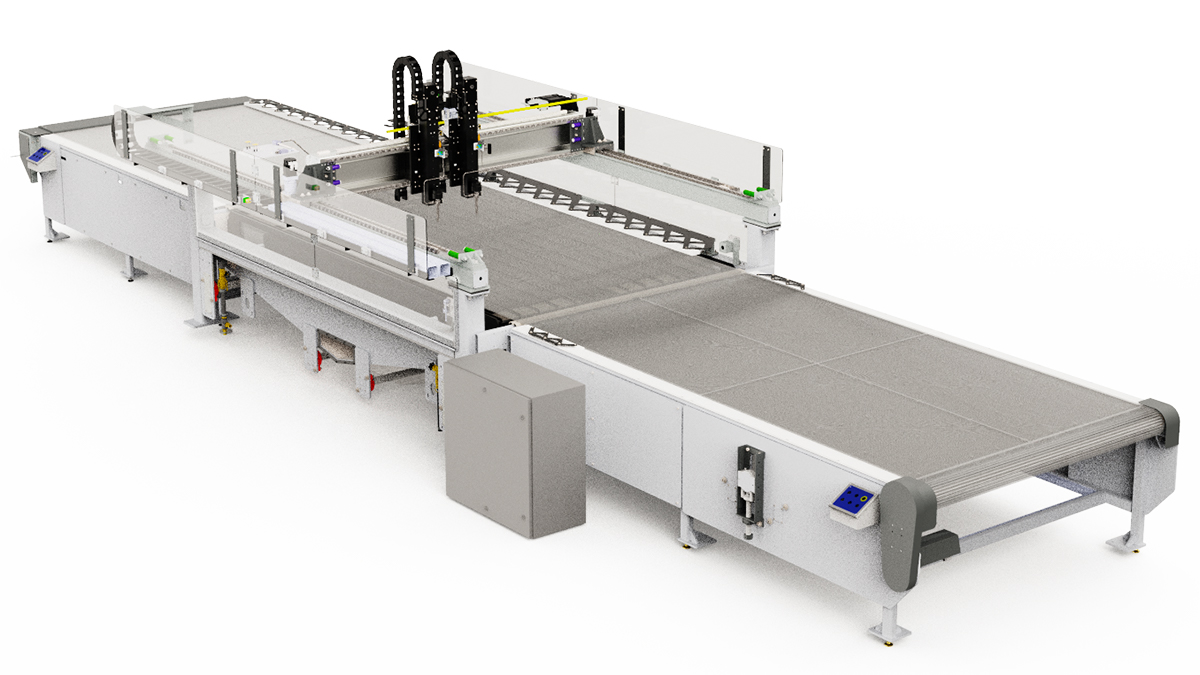

Custom Waterjets

Our Companies

WARDJet is part of AAG Tailored Cutting Solutions. We are global leaders in modular CNC technology with a vast technical support network.

Partnerships

Product Brochures

Get a copy of WARDJET's latest product brochure. Learn all about our extensive range of WARDJet CNC waterjets. Choose between our 6 big series - A-Series, X-Series, M-Series, H-Series, J-Series, and L-Series.