High Production Ready

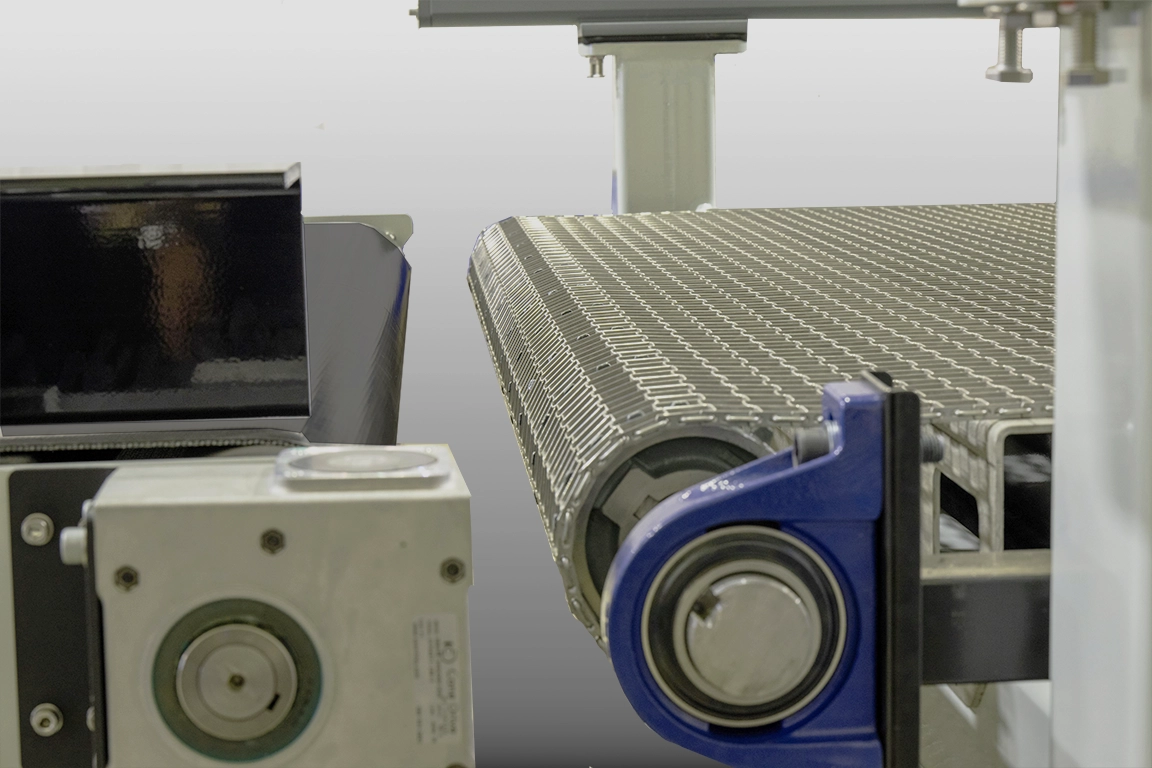

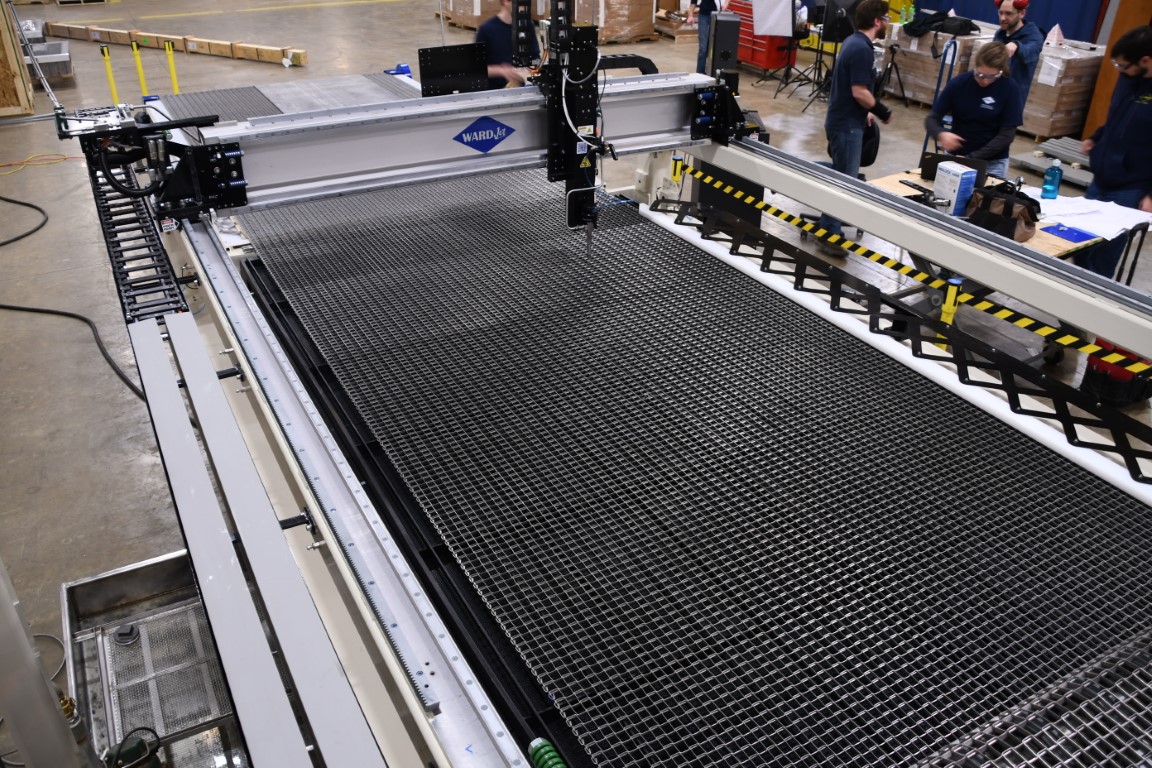

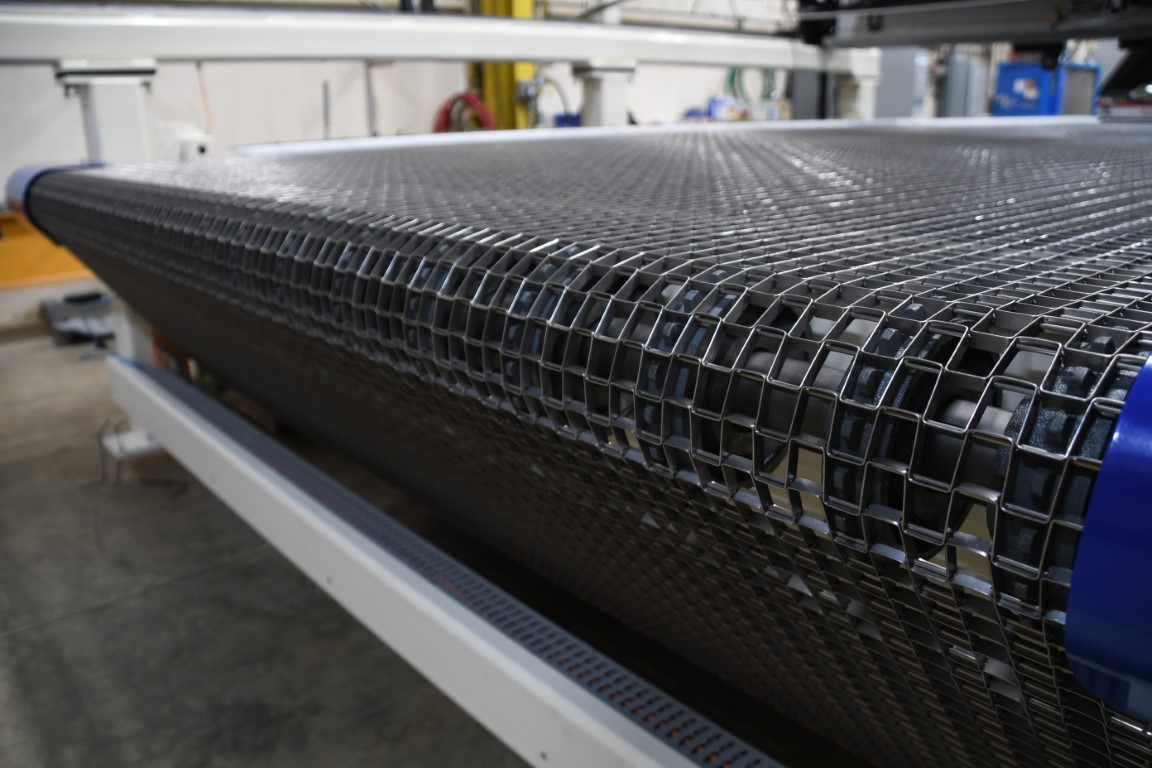

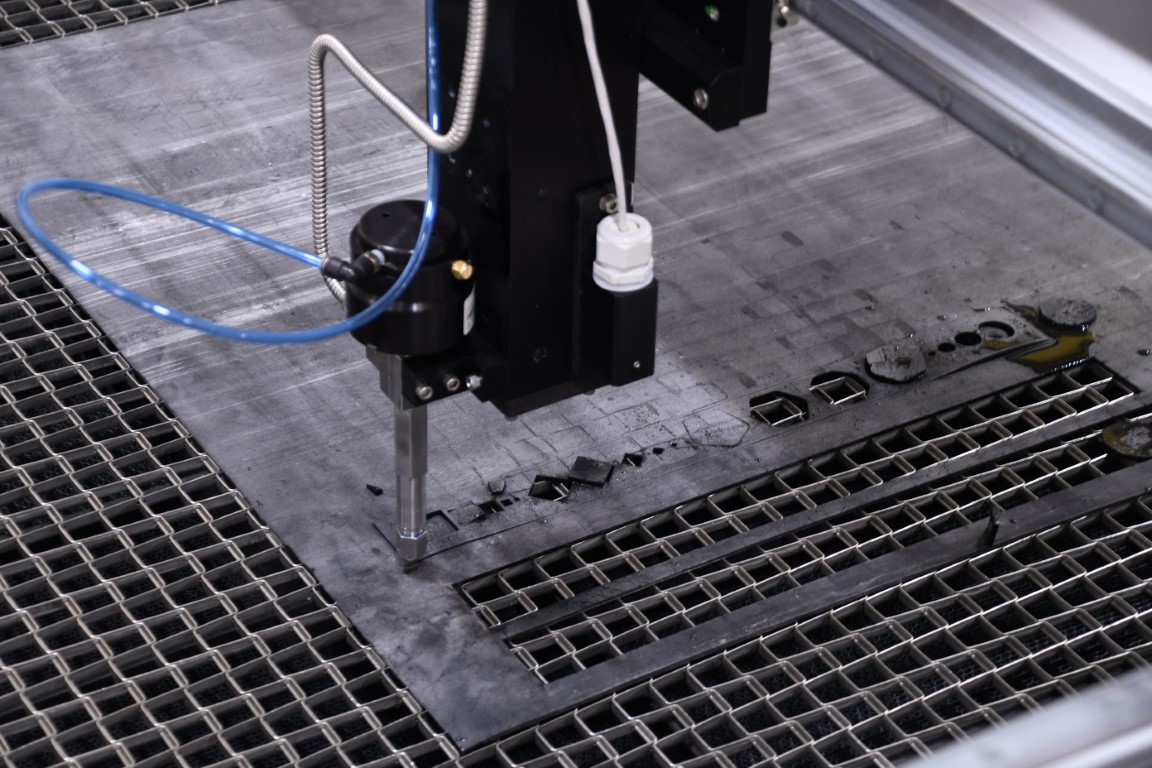

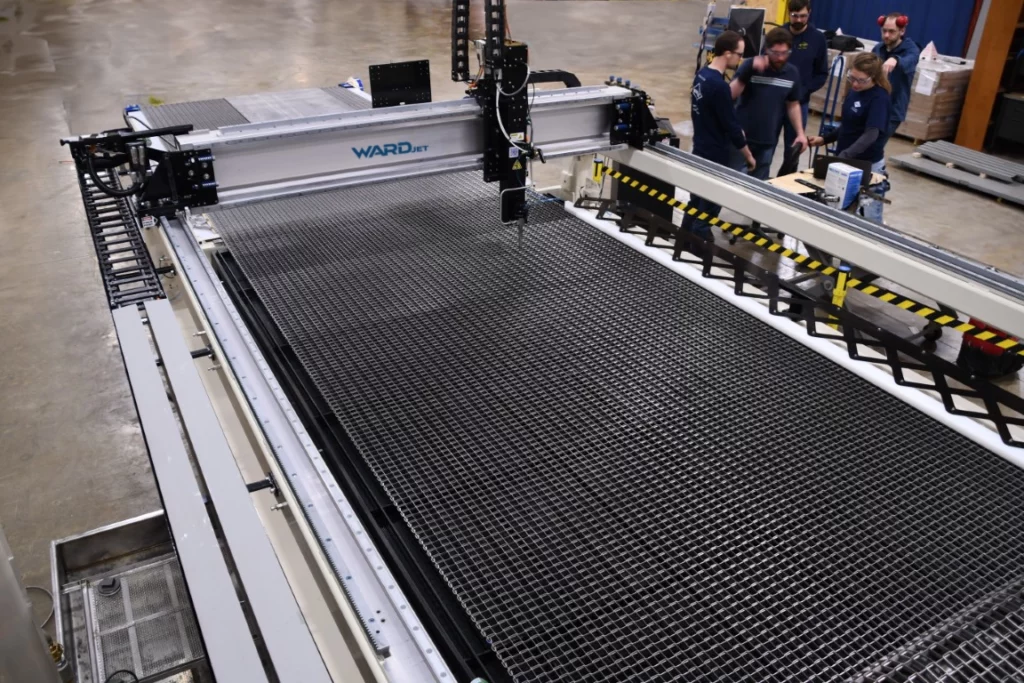

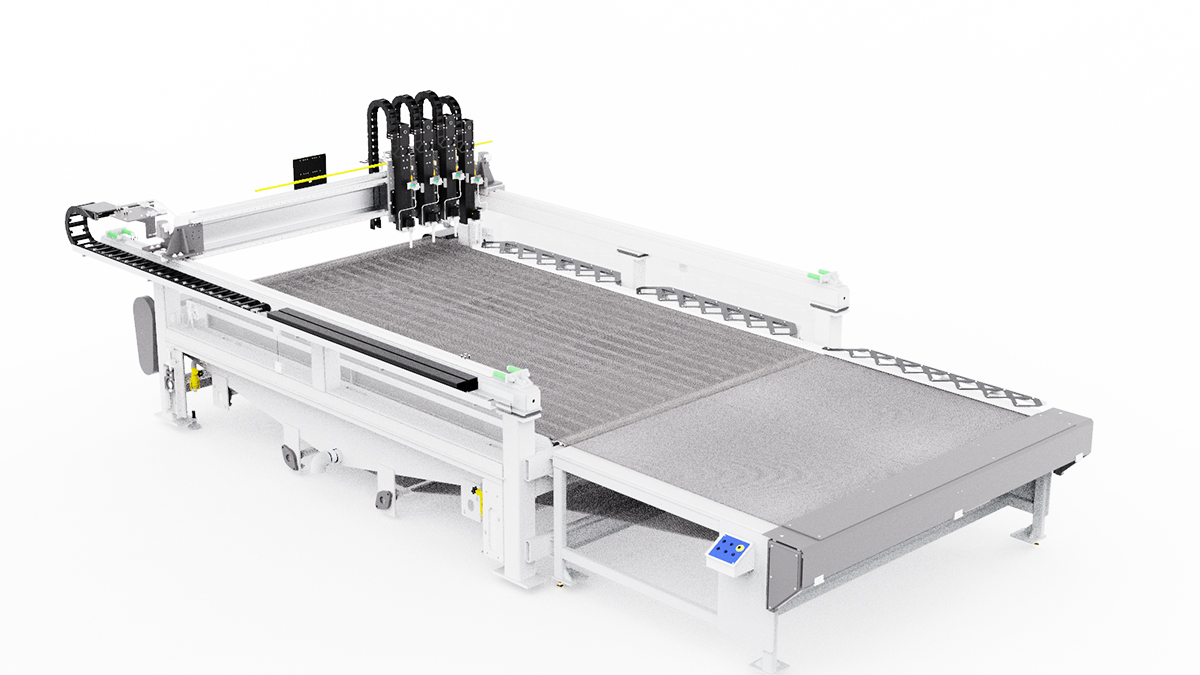

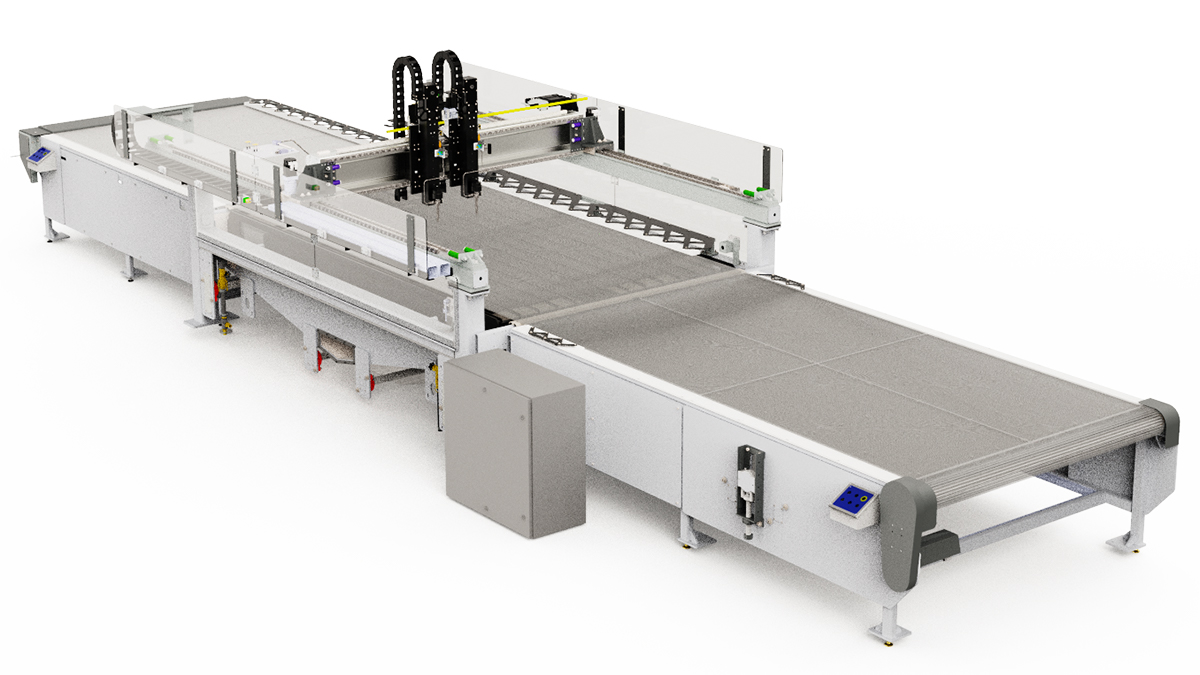

The J-Series has been designed specifically for a high-production water-only environment. A sloped, stainless steel bottomed tank and chain feed system over cutting bricks reduce material wetting and splash back, while moving the material in and out of the cutting zone to virtually eliminate time between cycles.

Tailored to You

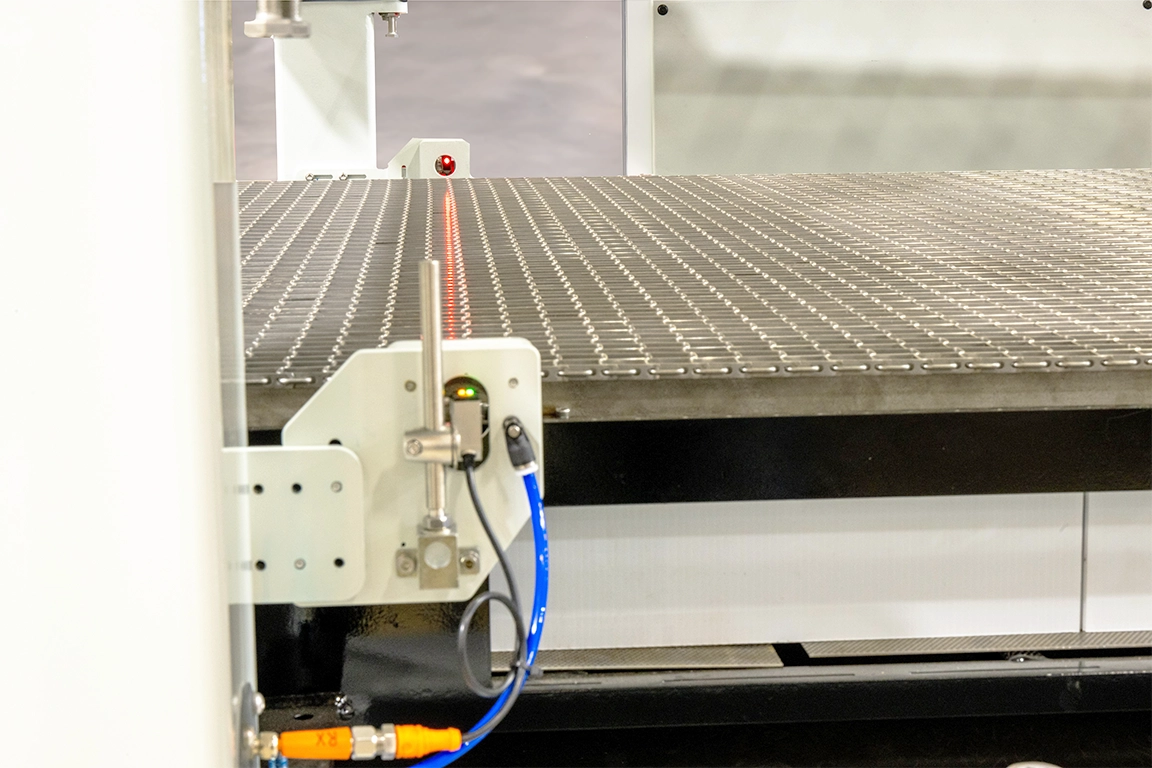

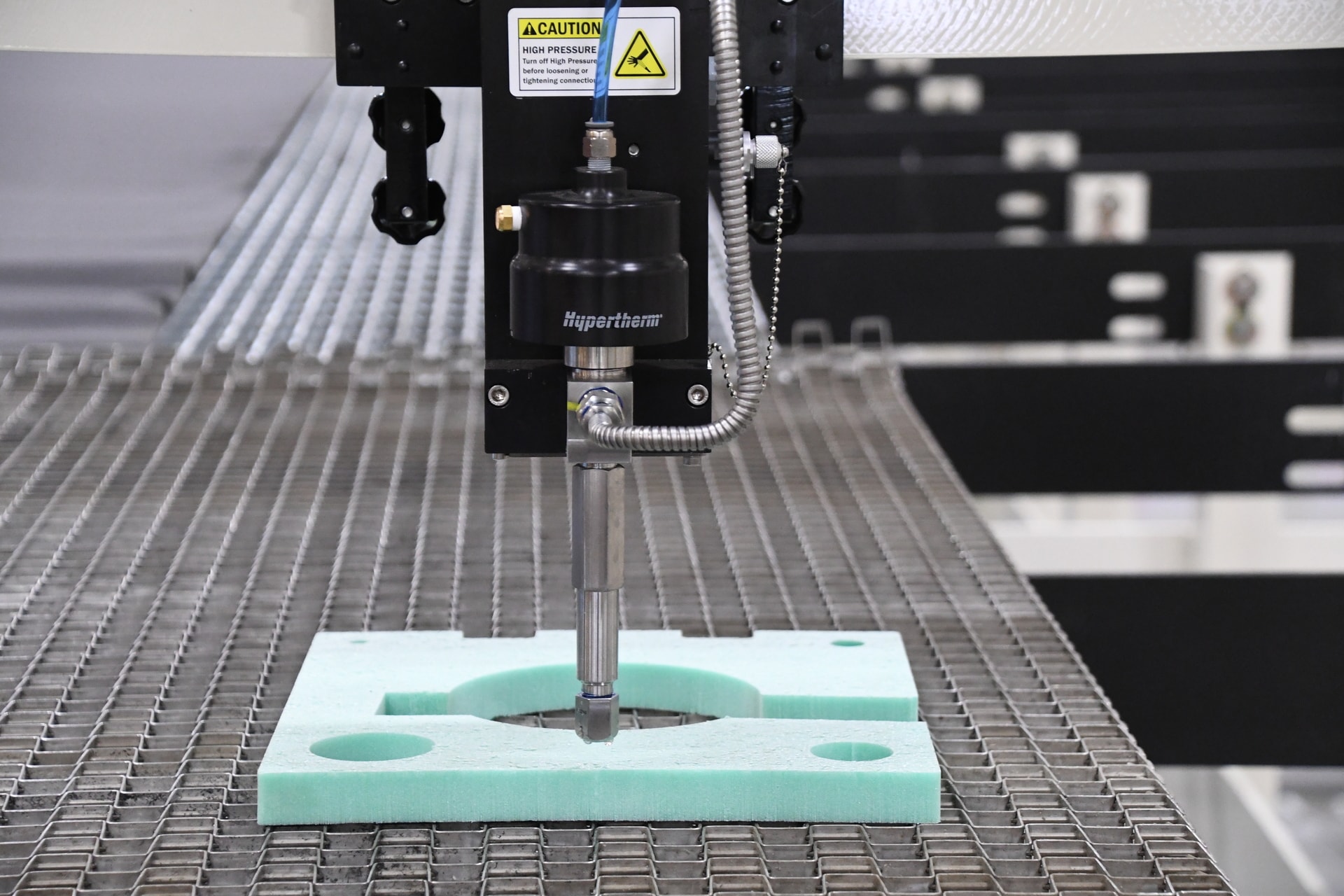

The J-Series has many ways to tailor the system to your needs. In-feed and out-feed table options, pinch feed rollers, and laser sensing are just some of the ways we can fit the system to our unique needs.

Cutting Versatility

The J-Series can allow for almost any configuration imaginable. Multiple cutting heads, spreader bars, and our APEX60 5-axis cutting head are just some of the options available on the J-Series.

J-128

Cutting area is 12.75’ (3.8m) in length x 8’ (2.4m) in width with 10” (.25m) in Z-Travel.

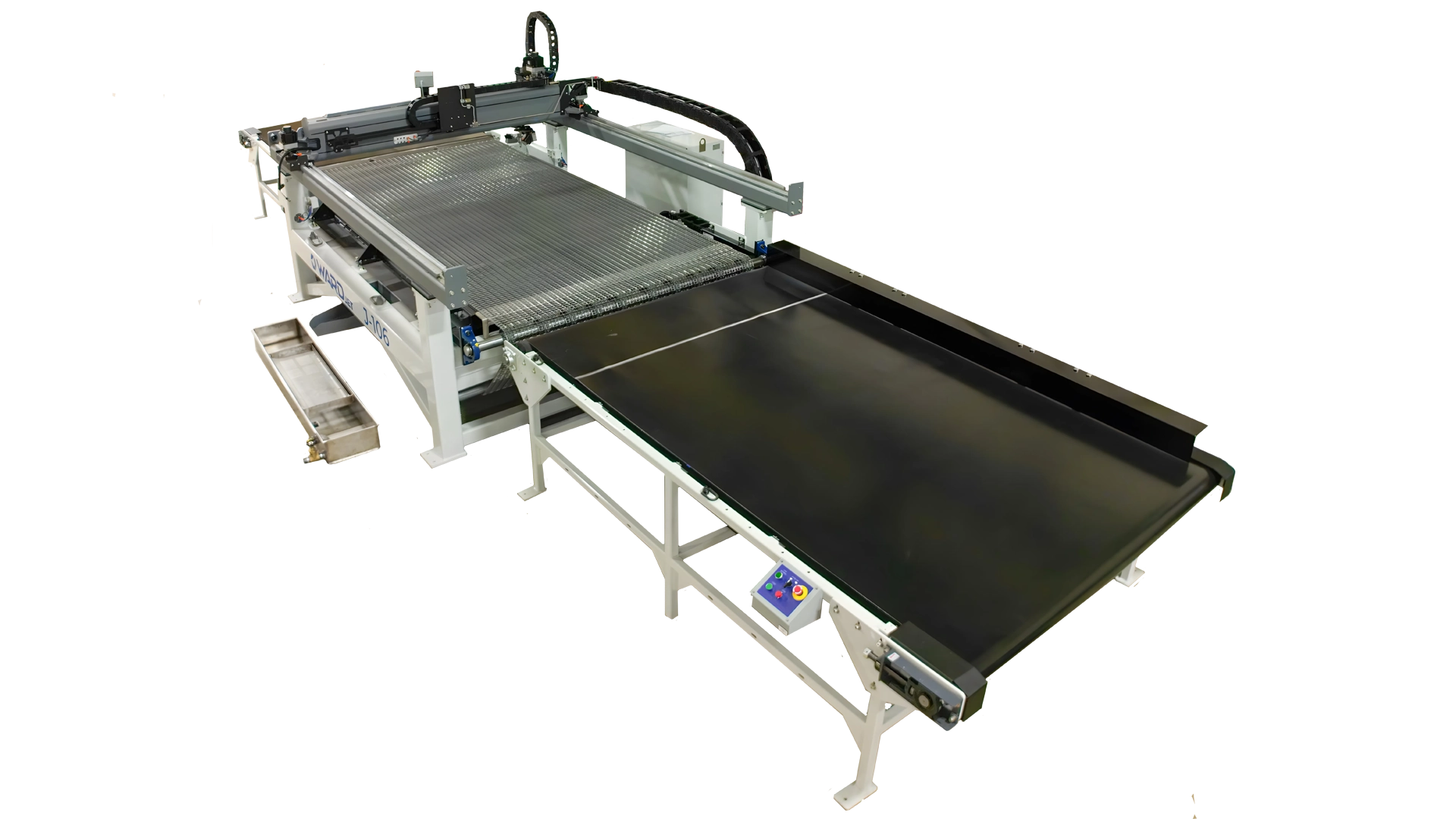

J-106

Cutting area is 11.5’ (3.5m) in length x 6’ (1.8m) in width with 10” (.25m) in Z-Travel.

Features & Benefits

The J-Series can reach speeds of up to 2500ipm with high acceleration. As water-only cutting tends to be high volume parts, the time to get from one part to the next is critical in reducing overall cycle time.

The J-Series drive system uses THK rails and precision helical rack-and-pinion drives for high speed and durability. You can be sure your J-Series system will run day in and day out with minimal need for upkeep.

The exclusive J-Series tank design directs all water and debris to a central drain location. From there, the J-Series offers a wide variety of wastewater solutions to suit your need. Recirculating washdown systems, paper bed filtration, and closed loop systems are all available.

A Complete Package

More than just a waterjet, our 30+ years of service and commitment comes "bundled" with our waterjet cutting systems.

UPGRADEABILITY

Waterjet systems and accessories engineered to scale with your business

UNLIMITED SUPPORT

Stop waiting for a technician. Maximize your uptime with remote support.

FREE TRAINING

1-on-1 training with waterjet professionals for as long as you own your waterjet.

ONLINE RESOURCES

Most comprehensive training and support documentation in the industry.

Perform Better

We invite you to learn more about how our J-Series lineup can help you perform better within your industry.

Get in touch

Product Brochures

Get a copy of WARDJET's latest product brochure. Learn all about our extensive range of WARDJet CNC waterjets. Choose between our 6 big series - A-Series, X-Series, M-Series, H-Series, J-Series, and L-Series.